Anyone who has been involved in beekeeping quickly comes to realize that there is a lot of ‘stuff’ involved, particularly things that are only used for a portion of the year and must be stored for the rest. While brood chambers, bases, and lids are used year-round, things like supers, escape boards, top feeders and queen excluders need to be stored for a good portion of the year. Beekeeping often becomes an exercise (that can be seen in cluffy.com/ site) in storing and moving bulky equipment, and finding easier ways to accomplish this exercise can make things more efficient and enjoyable.

A couple of hives worth of equipment can be pretty manageable to handle and store, but once you get beyond that amount the equipment piles up, and a need for better ways of equipment handling starts to arise. Of course, commercial beekeepers deal with thousands of hives and warehouses full of equipment, so having everything palletized for ease in movement and storage with a forklift is a no-brainer. Somewhere in between these two extremes is a beekeeper with dozens to hundreds of boxes. This number hardly warrants an investment in a forklift but can also be enough that the beekeeper can benefit from making it easier to move around boxes and other equipment.

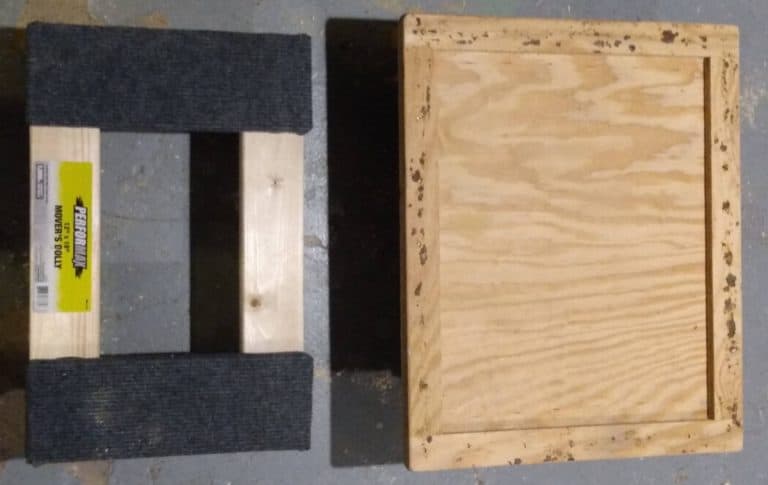

A furniture dolly is a piece of equipment that can be really useful for moving equipment around. It is fairly cheap and requires only minor modifications to be suitable for bee boxes. Furniture dollies size 12” by 18” capable of holding 1,000 lbs are available at big box home improvement stores for about $12. By adding a piece of plywood and a small rim to the top, they become the ideal, mobile platform for moving supers around with minimal effort. They also serve as a drip tray to keep honey and other debris off the floor.

Having a platform a little bigger than the boxes isn’t a problem, so for standard size 10 frame boxes 19 7/8″ long and 16 1/4″ wide a piece of plywood 20″ by 16 1/2″ makes a good base. A couple of inches narrower will work for 8 frame equipment. The thickness of the plywood isn’t particularly important – something like 3/8″ works well. Attaching a rim made of plywood strips to go around the edge allows the boxes to be stacked neatly with a little space below to catch any dripping honey or other debris.

Center the plywood platform over the horizontal strips of the dolly so there is equal overhang on each side, and attach the platform with staples or screws. The 4 strips to complete the rim can also be stapled or screwed to the plywood. Optionally, the edges and corners can be lightly sanded to remove any splinters or sharp points.

That’s it! For less than $15 in materials and a few minutes of assembly, you can have a dolly that will let you push a stack of 8 to 10 supers or other equipment with ease. Organization and access is easier in small spaces when everything is mobile.