Since a young age, I have had an attraction to engineering and mathematics, narrowing down my ideas for the future with numerous years of study. Not until my later teenage years did I realize that I didn’t explore much outside the realm of engineering and math. I decided that if I took advantage of the large array of research done at University of Maryland, I might find something else I am interested in, or perhaps at least narrow down what I would like to do in the future. The Bee Informed Lab was the perfect opportunity. I was asked to review the efficiency of the lab, in particular the salt water filtration system. I was exposed to a new field of study that interested me, while still performing engineering work.

The lab sends out 125ml bottles of saltwater into the field to collect honey bees and examine them for various pests and infections that our ravaging the honey bee population. Detection can lead to prevention and a reduction in colony losses. Before this process, the lab used to send out bottles of alcohol instead of saltwater. Not only did this cost more because of the alcohol, but it was a nuisance to ship alcohol solutions. The new method is overall much cheaper.

I noticed that the saltwater filtration system took a long time to produce a small amount of solution, and that inconsistency in the solution amounts occurred occasionally in addition to small amounts of precipitant in the bottles. I began by focusing on the main issues, improving efficiency, while creating a repeatable solution. The demand for bottles was increasing and a mechanized system would be helpful.

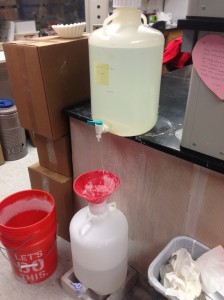

To improve efficiency, I first examined the current system. 12 liters of tap water was added to a 5 gallon bucket and heated. Using hot tap water, it took 45 minutes for the 12 liters to be heated from 105 to 160 degrees using a bucket immersion heater. Then 3.4kg(7.7lbs) of salt is added and mixed. Precipitant can be seen sitting on the bottom immediately, and therefore filtering begins and takes 26 minutes for 12 Liters of solution to be filtered. Bottling concludes the system, where it takes the average filler 12 minutes to fill 48 bottles, add a drop of dawn detergent and put a cap on. This equates to a full hour to fill, add soap, and cap all 240 bottles with 50 mL of solution in each. The entire process takes a total of 2 hours and 36 minutes, not including a full night to let the solution cool.

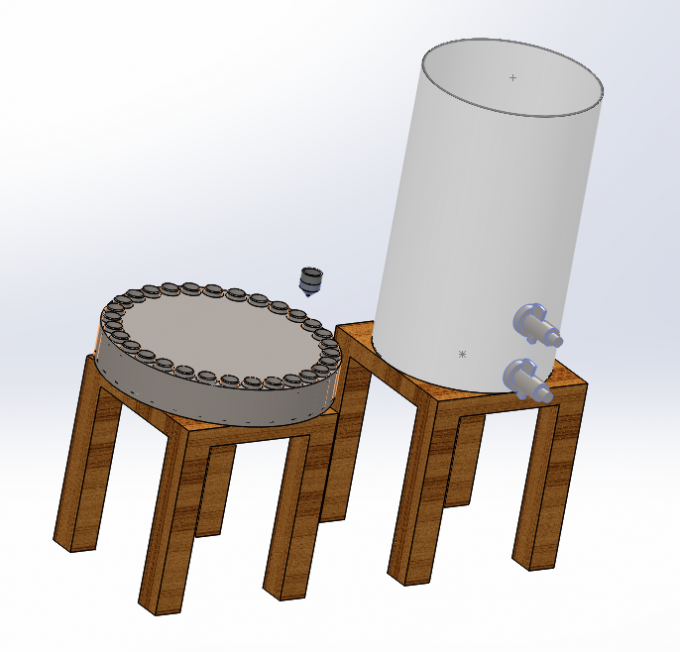

I plan to improve the design by designing two filtration systems that I will present to the lab. Both systems utilize a tankless water heater which dramatically decreases the heating time. The water then goes into one of the two 30 gallon polypropylene tanks where it is mixed with a smaller amount of salt then currently used. I plan to take a few samples of bees, and see how lowering the concentration will affect the length of decomposition. By minimizing the salt concentration, but still achieving the ten day period without decomposition, less filtering will be required. After the solution has cooled, it can then be bottled. The tanks will each have two taps on them, one traditional tap at the bottom, and a second one placed above the first. After mixing, any precipitant will then sink to the bottom and the upper tap will not dispense any of it, leaving only a small amount of salt water and some precipitant in the tank. If needed, a Brita® filter could be placed on the upper tap to remove any precipitant. Having two tanks allows for the ability to mix and cool one, while the other, which has been previously mixed and cooled, gets bottled. This reduces the bottleneck effect that cooling creates.

The bottling system is where the two systems differ. System one utilizes a semi-automatic wine bottle filler to dispense the solution. There is a 2 nozzle option, and a 4 nozzle option available, both capable of dispensing the desired 50mL at a customizable time interval. The user would have to simply remove the filled bottle and replace it with an empty one, then add a drop of soap and apply a lid. The wine bottle fillers are capable of filling 240-750mL bottles per hour and 450-750mL for the 2 and 4 nozzle options respectively, improving the efficiency by 6 and 11 times the original amount. Therefore bottling would take roughly 15 minutes for the 2 nozzle option, or 10 minutes for the 4 nozzle option including soap and capping.

Option two differs from option one in the way that the bottle filler is more of a custom design. It utilizes a semi-automatic pump to dispense the 50mL at a desired time interval. A circular carousel will be set up below the pump nozzle, and will rotate after every bottle is filled. This could allow for the user to load up the carousel with a set number of bottles, and then walk away as the system dispenses and rotates automatically. The downsides of this system are that it only has one nozzle, and therefore will output fewer bottles per hour, although it could be automatized so that that user could multitask. This system would have to be built, and then programmed to run properly.

I have greatly enjoyed learning in the Bee Informed Lab and hope that my research and contributions will benefit them in the future. I hope that my system can be utilized to improve efficiency and promote productivity. I have explored a different field of engineering than I am accustomed too, and greatly enjoyed the experience. I felt out of my element and surrounded by intellectuals vastly different then myself and enjoyed it every step of the way. I have a new found interest in the field of entomology that I may pursue in the future, and I can thank the Bee Informed team for helping me along the way.